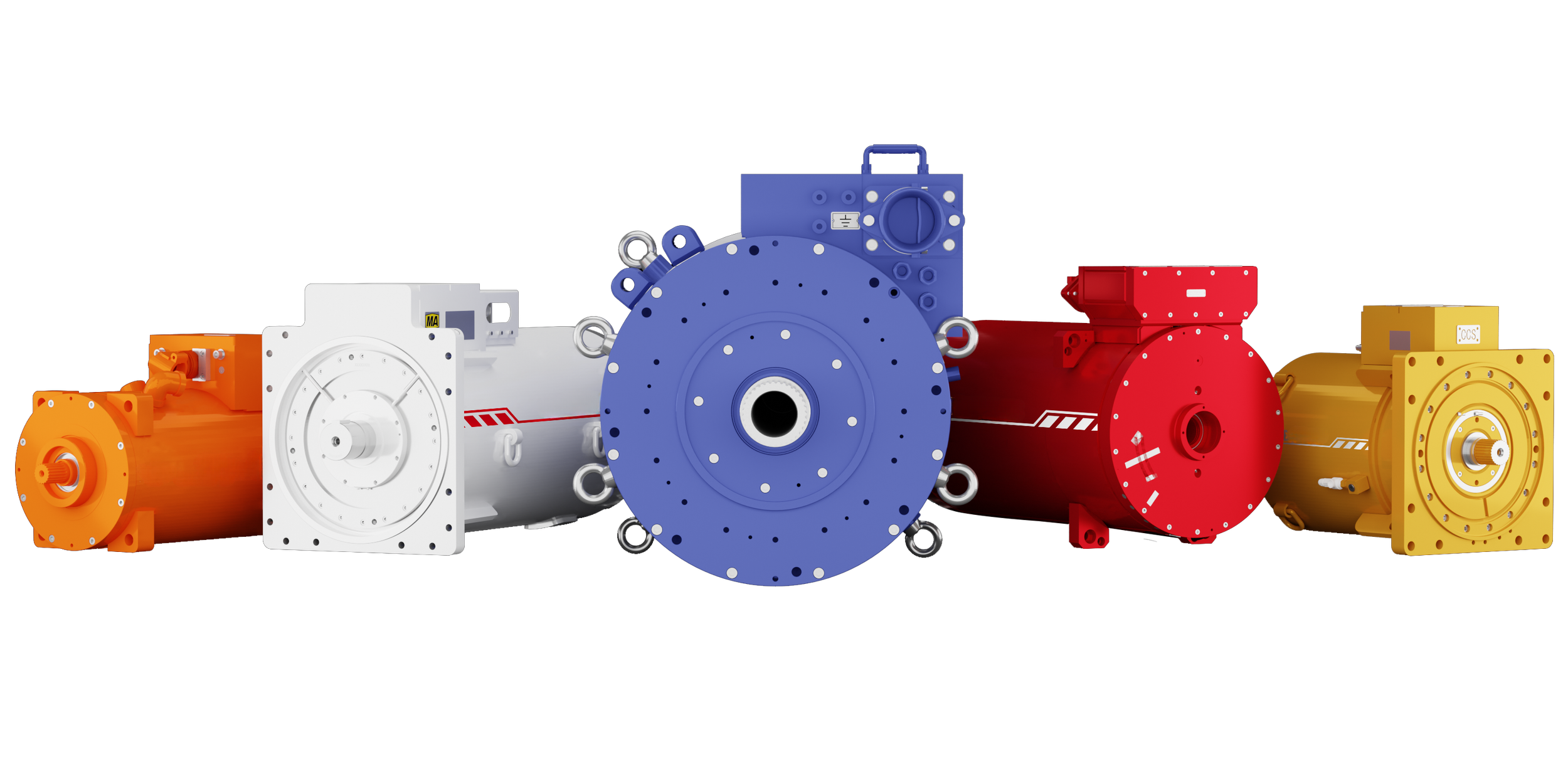

Standard solutions

Custom engineering.

Drivewerx® delivers uncompromising electric drive solutions, from cutting-edge PMSM technology to rugged induction motors, even with fully integrated inverter systems, precision-engineered and built with total manufacturing control.

Permanent

Magnet

Technology.

Maximum Efficiency, Minimum Footprint.

Our premium Permanent Magnet Synchronous Machines

provide unmatched efficiency, torque density and compactness.

Typical Industries

Marine | Power Generation | Oil & Gas | Heavy Industry | Mining | Water & Wastewater

.

M A X I M U M E F F I C I E N C Y . M I N I M U M F O O T P R I N T .

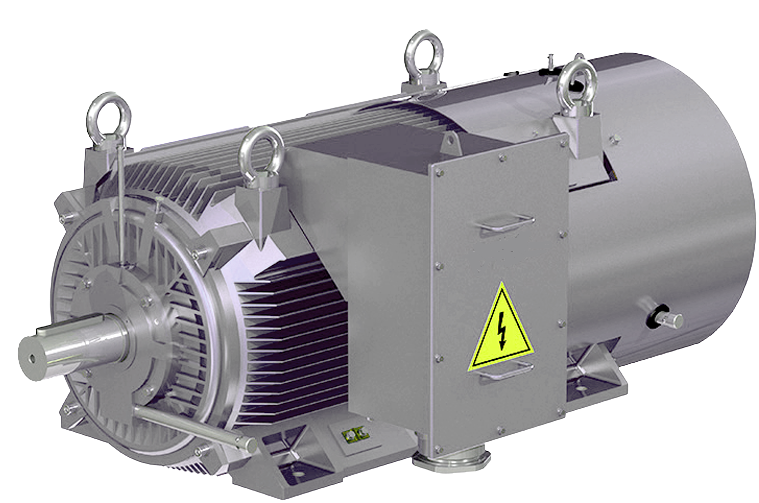

Asynchronous

Induction

Motors.

Proven, Durable & Reliable.

Standard and customized electric machines engineered for heavy-duty applications with long service life and mechanical robustness.

Typical applications

Main Propulsion | Thrusters | Pumps | Cutter heads | Plastics machinery | Winches | Fans | Compressors

.

P R O V E N. D U R A B L E. R E L I A B L E.

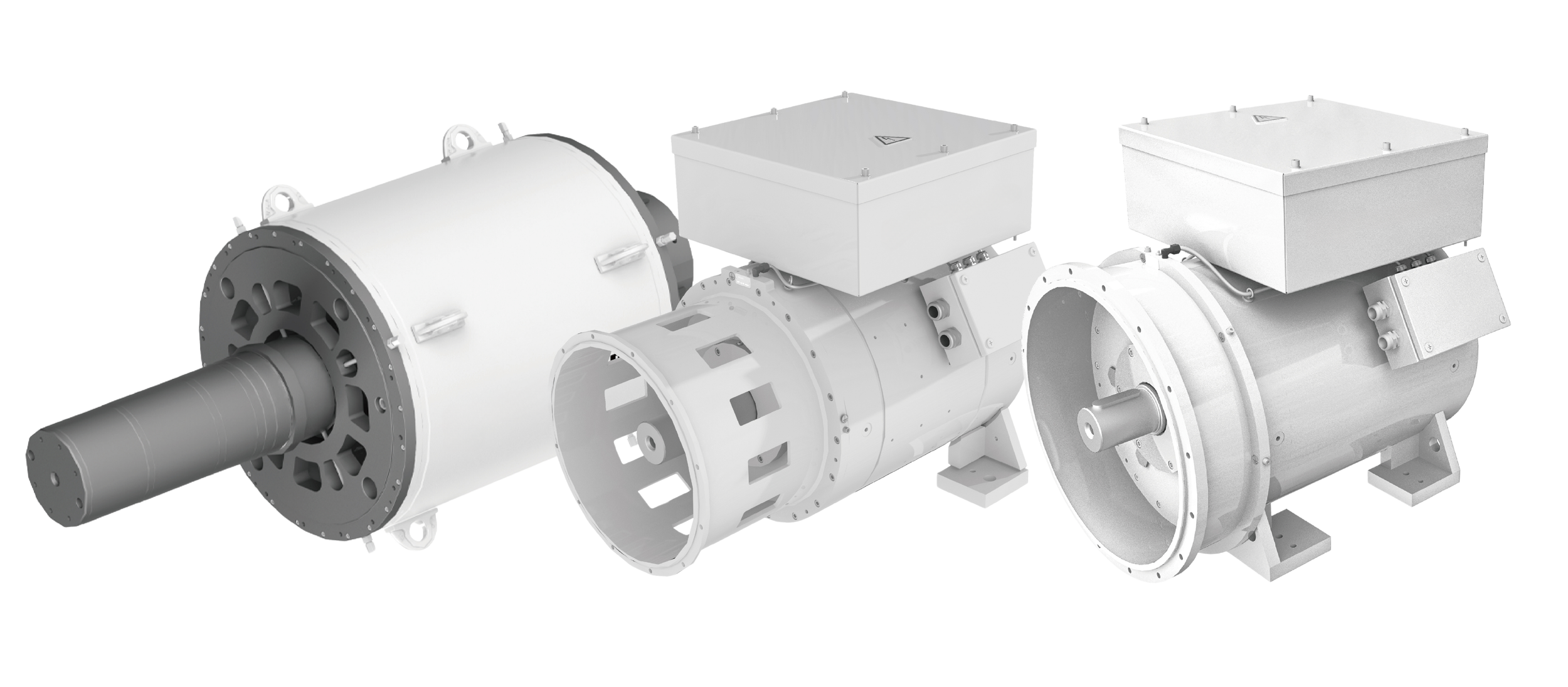

Integrated

Inverter

Solutions.

One Compact, Unified Drive Solution.

Fully integrated, stand-alone motor with inverter systems combine the electric machine and drive into a single compact solution. A unique capability enables delivery of both PMSM and induction motors with a seamlessly integrated inverter, reducing footprint and serviceability.

Key features

Optimized torque and speed control

Reduced cabinet dimension and cabling

Improved EMC performance

Significantly lower overall system footprint

Lower and easy maintanace

Modular system architecture

Typical Industries

Marine | Power Generation | Oil & Gas | Heavy Industry | Mining | Water & Wastewater

.

C O M P A C T M O D U L A R D R I V E S O L U T I O N.

Custom

Solutions &

Engineering.

Built to your exact specifications.

Each Drivewerx® custom-engineered solution delivers premium, built-to-spec performance through complete design freedom, vertically controlled manufacturing, precision engineering, and close technical collaboration. Every system is engineered around the application’s environmental, operational, and mechanical requirements.

Capabilities

- Mechanical customization

- Cooling design

- Electrical & control engineering

- Environmental adaptation

- Intergrated drive, Gearbox, Pully configurations

Co‑Engineering Workflow

Requirement definition → Simulation → Mechanical interface → Prototyping → Production

Typical Applications

Propulsion | Thrusters | Pumps | Compressors | Conveyors | Hoisting | Mills | Crushers | Mixers

.

B U I L T - T O - S P E C I F I C A T I O N.

Applications

-

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more.

-

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more.

-

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more.

-

Item description

-

Item description